Advanced Planning System (APS)

Custom planning and schedulingWhy is it so difficult to plan properly?

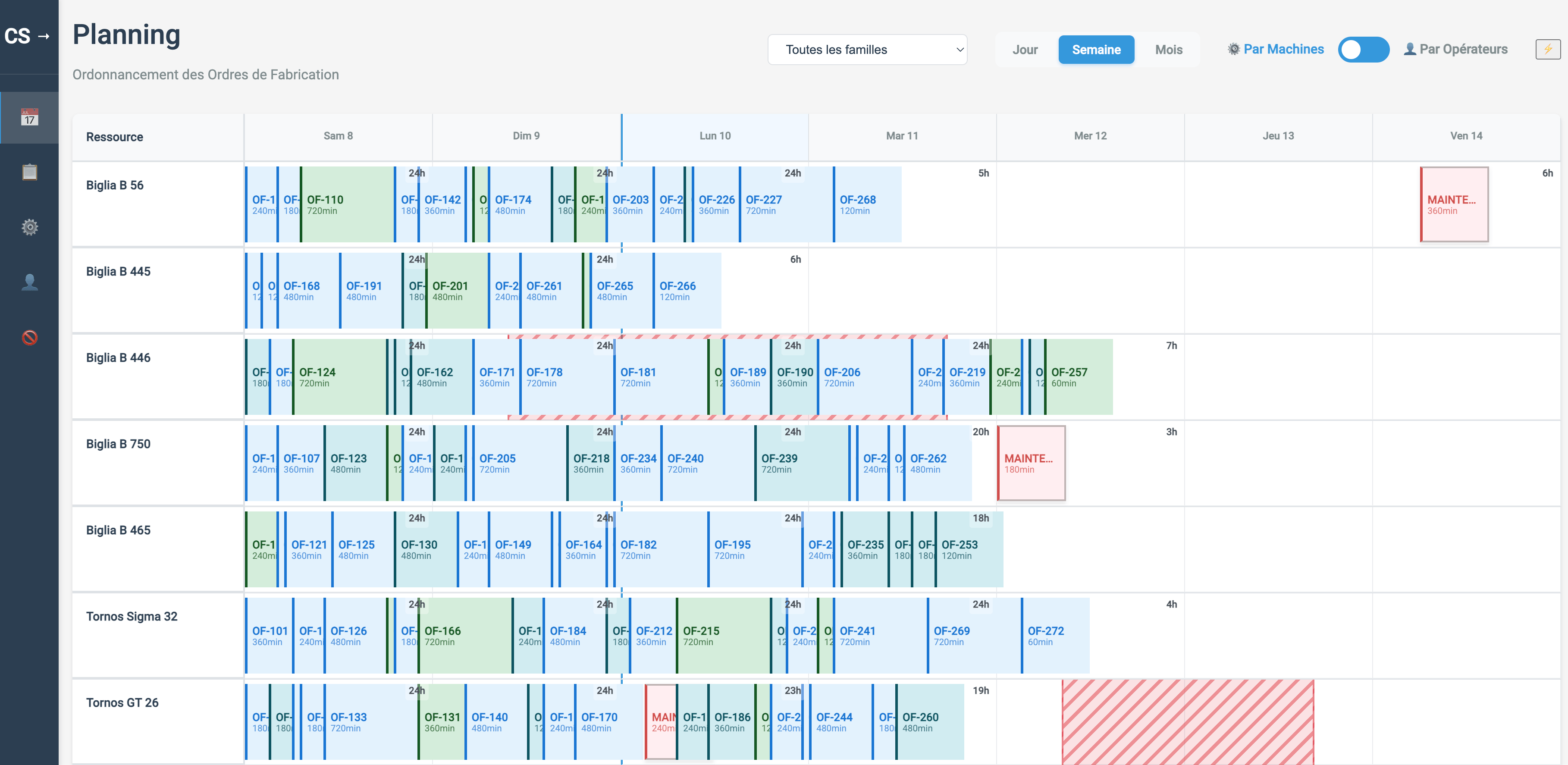

Resource planning requires managing vast amounts of data. You must juggle customer orders, production capacities and routings, line changeover times, and staff skills. Stock levels, personnel availability, machine status, and production constraints must be verified at all times.

This initial complexity is compounded by daily disruptions: sick leave, equipment breakdowns, urgent new orders, or supply shortages can disrupt established schedules. Even experienced planners struggle to adapt quickly, let alone re-optimize or make schedules robust against these unforeseen events.

Faced with customers demanding quick responses and tight deadlines, the combinatorial complexity becomes impossible to manage manually. Excel spreadsheets are no longer sufficient to maintain reliable and efficient schedules. Planning becomes a true strategic challenge, directly linked to operational performance and customer satisfaction.

Why has advanced planning become essential?

Effective planning is a strategic issue: it directly impacts profitability, responsiveness, and service quality. However, without APS, training a planner takes over a year, and this dependency poses a real risk. Facing market demands (speed, quality, costs), an APS becomes vital to digitize business expertise. It centralizes data and calculations to ensure reliability and performance, while offering responsiveness to disruptions and anticipation capability through robust schedules.

The Advantages of an Advanced Planning System

Reduce risk

When a single person holds the planning expertise, the company becomes entirely dependent on that individual. A vacation, departure, or sick leave can paralyze operations. By centralizing business knowledge in an ergonomic tool with built-in checks and intelligent automation, an APS makes planning more accessible. Training a backup planner becomes faster, which reduces operational risk while preserving critical know-how.

Optimize resources

Having the right resource at the right time is a constant challenge. Planners must continually balance delays, overtime, and customer priorities. An advanced planning system allows you to simulate different scenarios and objectively assess their performance through key indicators. The result: optimal resource utilization and better adaptation to business fluctuations.

Gain responsiveness

When facing disruptions — machine breakdowns, supply shortages, order changes — responsiveness becomes crucial. APS optimization algorithms can recalculate a coherent schedule in seconds. The company gains flexibility and peace of mind while limiting the impact of disruptions on production.

Improve customer satisfaction

Smooth, optimized planning directly translates to shorter lead times, enhanced service quality, and more reliable commitments. By improving operational control, companies increase customer satisfaction and loyalty — a decisive advantage in competitive markets.

Limitations of Standard APS

Market APS solutions often address generic needs. They offer standardized planning algorithms designed to work across maximum industrial contexts. This approach enables rapid implementation but quickly finds its limits when facing specific business constraints.

Every company has its own production, logistics, or maintenance rules. As soon as these constraints become complex — dynamic priorities, fine-grained skill management, strict regulatory constraints — standard algorithms struggle to generate truly optimized schedules. This is where a custom approach makes perfect sense.

APS Starter: a ready-to-use foundation for your custom projects

To quickly address your scheduling and planning needs, we offer APS Starter, a lightweight and extensible solution. It allows you to visualize and test your schedules while concretely demonstrating the capabilities of an APS tailored to your company.

Ideal for validating the feasibility of a scheduling project before considering custom development. You experience optimization benefits without heavy commitment and have a solid foundation to evolve toward a more personalized solution if needed.